Products

AGENACOMP®

Your home-compostable & bio-based biopolymer for flexible packaging

AMITROPLAST®

An important ingredient in your bioplastic compound

AGENACOMP®

– Properties and Applications

Our expertise in BIOPLASTICS

AGENACOMP® combines thermoplastic starch with a biodegradable polymer which can be implemented in your existing set-up. It has excellent mechanical properties regarding flexibility and formability and is home-compostable. AGENACOMP® can be tailored to meet the specific requirements of different applications, such as flexible packaging films, mulch films, or 3D-printing.

Bags

Proctective Packaging

Non-woven Fibers

Multilayer Films

3D-Print

AGENACOMP®

– Your compound for film extrusion

Our expertise in BIOPLASTICS

Our AGENACOMP® is home compostable and contains up to 50 % renewable materials. It allows to extrude films of less than 10µm by standard film extrusion equipment.

Our Starch

- Renewable and regional raw material

- Non-genetically modified

- Starch from Austria

Our AMITROPLAST®

- Specialized thermoplastic starch

- The way to your unique biopolymer compound

Our AGENACOMP®

- Combination of AMITROPLAST® technology with bio-degradable polymers.

Your Film

- Biodegradable

- Home-compostable

- Bio-based

Product Characteristics

AGENACOMP® is easy to process in your existing set-up and has excellent mechanical properties.

- Natural

- Biodegradable

- Versatile

- Home-compostable

- No microplastic residues

- Colorable

- Recommended for multi- & monolayer

| Density (g/cm3) | approx. 13 |

| Particle size (mm) | approx. 4 |

| Melt Volume Rate MVR (190 °C, 2.16 kg) (cm3/10 min) | approx. 2 |

Product Types

AGENACOMP® F30

- Excellent mechanical properties, comparable to PE

- Perfect for mulch films

AGENACOMP® F40

- Bio-based carbon content 33%

- Good processability with high starch proportion

AGENACOMP® F50

- Sustainability boost: Bio-based carbon content 40%

- Cost efficient: High starch content

AGENACOMP® F51

- Sustainability boost: Biobased carbon content >50%

- Easy to process with conventional processing equipment

AGENACOMP® F61

- Sustainability boost: Bio-based carbon content >60%

- Easy to process with conventional processing equipment

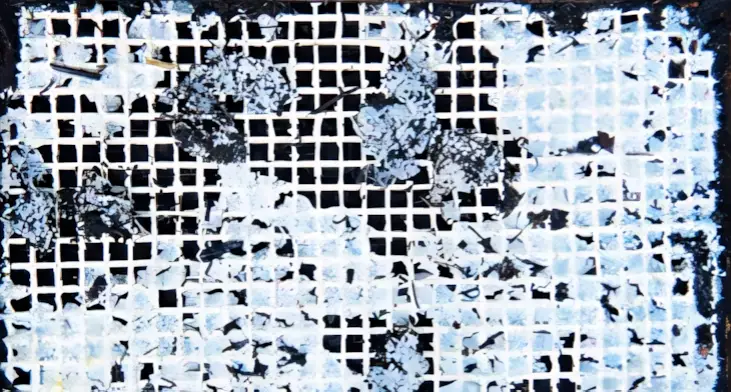

Bio-degradation & Composting

Home-compost conditions (28 °C and less) of a 15 µm film AGENACOMP®.

Start

After 2 Weeks

After 4 Weeks

Downloads

AMITROPLAST®

– Properties and Applications

Thermoplastic Starch

With the AMITROPLAST® product family, AGRANA provides a user-friendly thermoplastic starch for extrusion, film blowing, injection molding and 3D-printing.

Our AMITROPLAST®products allow users to incorporate significant amounts of thermoplastic starch into bioplastic compounds and thus, to create tailor-made polymer compounds that are processable by using standard polymer equipment and capable of adding extra value to innovative products.

Product Characteristics

AMITROPLAST®, thermoplastic starch can be added to polymers to increase the bio-based content and improve the biodegradability.

- 100% Bio-based

- Cost-effective

- Biodegradable

- Versatile

Our Starch

- Non-genetically modified

- Renewable and regional raw material

- Starch from Austria

Our AMITROPLAST®

- Biodegradable

- Home-compostable

- The way to your value-added bio-polymer compound

Your Compound

- Combination of AMITROPLAST® technology with bio-degradable polymers.

Your Product

- Tailor made products with customized properties

AMITROPLAST®

– Your thermoplastic starch for extrusion and injection

Extrusion & Thermoforming

- Carrier bags

- Fruit and vegetable bags

- Protective packaging

- Wastebags & bin liners

- Non-woven fibers

- Technical films

- Forestry applications

- And many more

Injection Molding

- Agricultural clips and guides

- Plant pots

- 3D print filament

- Cutlery

- Packaging

- Sanitary products

- And many more

Product Characteristics

Bio-based

AMITROPLAST® has a bio-based carbon content of 100% and allows you to reach easily 40 % of renewable resources or more in your products.

Film

A 20µm film, based on a compound that consists of 40% AMITROPLAST® and 60 % biodegradable polyester results typically in an extensibility of approximately 300% and a tensile strength of 35 MPa.

No Smoke

The new technology of AMITROPLAST® significantly reduces the development of smoke during film blowing.

Stretching

Stretching increases the tensile strength, whereby values in a range of 60 MPa are accomplished (depending on the applied draw-ratio).

Injection Molding & Thermoforming Recyling

Compounds containing AMITROPLAST® can be recycled and fed back into the process.

| Density (g/cm3) | approx. 13 |

| Particle size (mm) | approx. 4 |

| Melt Volume Rate MVR (190 °C, 2.16 kg) (cm3/10 min) | approx. 2 |